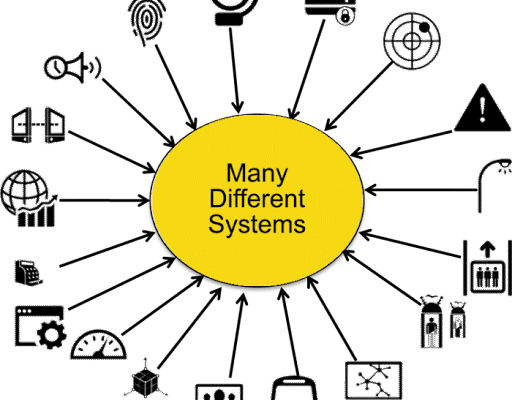

System upgrades in industrial environments go far beyond replacing old hardware. Control system integrators build multi-layered support frameworks that ensure precision, reliability, and performance from the field wiring to advanced data layers. Each layer adds a safeguard that helps facilities transition seamlessly while maintaining uptime and improving efficiency in operations that depend on custom PLC and automation technologies.

Field I/O and Instrument Layer Verification During Control System Upgrades

The foundation of any control upgrade starts with validating every field I/O point and instrument. Before integrating new PLC hardware, control system integrators verify wiring continuity, grounding integrity, and signal accuracy from transmitters, sensors, and valves. This process confirms that all external devices communicate correctly with the upgraded system, preventing data loss or false readings that could disrupt production.

Field verification also ensures proper scaling and calibration between field instruments and the new control logic. Testing each signal input and output under actual operating conditions allows integrators to identify discrepancies early, saving extensive troubleshooting time once the system goes live.

Control Hardware and PLC/Rack Substitution Layer Ensuring Seamless Transition

Upgrading to new PLCs or rack systems, such as Rockwell Allen Bradley PLC platforms, requires precise planning. Integrators assess hardware compatibility, cabinet spacing, and I/O mapping to make the transition smooth and efficient. The replacement process includes cross-referencing terminal points and reassigning addresses so that existing field wiring aligns perfectly with the new controllers. This layer of substitution not only preserves the plant’s infrastructure but also introduces modern diagnostics and communication capabilities. Using updated PLC hardware ensures faster scan times, increased memory, and greater flexibility for future expansions—all critical benefits in modern industrial automation.

Network Communication Backbone Redesign for Optimized Signal Pathways

A system’s communication backbone determines how efficiently control devices exchange information. During upgrades, control system integrators often redesign industrial Ethernet or ControlNet topologies to optimize data flow and minimize latency. Properly structured networks eliminate signal congestion, improving responsiveness between PLCs, HMIs, and remote I/O systems.

This redesign may include upgrading switches, isolating traffic between segments, or introducing redundancy protocols. The result is a resilient network that supports both real-time control and secure remote monitoring—an essential improvement for modern facilities adopting advanced PLC programming standards.

Operator Interface and HMI Layer Refresh Preserving User-familiar Workflows

Operator interfaces serve as the bridge between human and machine. During an upgrade, integrators redesign HMI screens to enhance usability while preserving the operator’s familiarity with existing workflows. Updated displays improve readability, add trend visualization, and include advanced alarm management functions that reduce human error.

The new HMI layer can also integrate multi-touch controls or remote access dashboards. By maintaining intuitive layouts and consistent color schemes, integrators ensure that operators adapt quickly to the upgraded system without retraining delays or performance slowdowns.

Motor Control Centre and Drive Schema Layer Alignment with Updated Architecture

Motor control centers (MCCs) and variable frequency drives (VFDs) often form the heart of industrial power control. During upgrades, control system integrators align drive communication protocols with the new PLC architecture, standardizing data exchange and fault diagnostics. This alignment ensures that each motor communicates efficiently with the control system while adhering to safety and performance parameters.

This layer also includes updating control schematics, wiring diagrams, and protective device configurations. Proper synchronization between drives and control logic enhances energy efficiency and extends the lifespan of the equipment. Facilities running complex machinery benefit from this structured coordination between power and automation layers.

read more : Tips to Optimise Your Smartphone Settings for Streaming Movies Without Buffering

Cybersecurity and Segmentation Layer Safeguarding Industrial Control Networks

With modern connectivity comes increased exposure to digital threats. Control system integrators strengthen cybersecurity by adding segmentation layers that isolate control networks from enterprise or internet-facing systems. This approach limits unauthorized access and reduces the risk of malware propagation.

Cyber defense strategies include deploying firewalls, VLAN separation, and user access control policies. Integrators also apply encryption for sensitive communications between custom PLC controllers and SCADA systems. These protective measures create a secure automation environment without compromising performance or data availability.

Data Aggregation and Historian Layer for Improved Operational Visibility

Modern upgrades go beyond control—they enhance decision-making. Integrators configure data aggregation layers that collect and store operational metrics from sensors, PLCs, and HMIs into centralized historian databases. These systems allow operators and engineers to analyze trends, detect inefficiencies, and forecast maintenance needs.

By integrating historian software with the upgraded control system, facilities gain long-term insights into performance metrics. The stored data becomes a valuable resource for process optimization and predictive maintenance, ultimately reducing downtime and improving overall efficiency.

Maintenance Support and Diagnostics Layer Enabling Proactive Fault Detection

A key benefit of working with experienced control system integrators is the addition of diagnostic layers that make ongoing maintenance easier. Integrated fault detection tools provide real-time alerts, error codes, and system logs directly within the control platform. This helps maintenance teams address issues quickly before they cause downtime.

Advanced diagnostics also support remote access, allowing engineers to troubleshoot from offsite locations. This capability minimizes response times and improves plant reliability. With expertise in what is PLC programming and its application in industrial automation, R.L. Consulting helps facilities implement multi-layered upgrades that enhance performance, security, and operational continuity from the field device to the control room.